- Overview

- Product Description

- Product Parameters

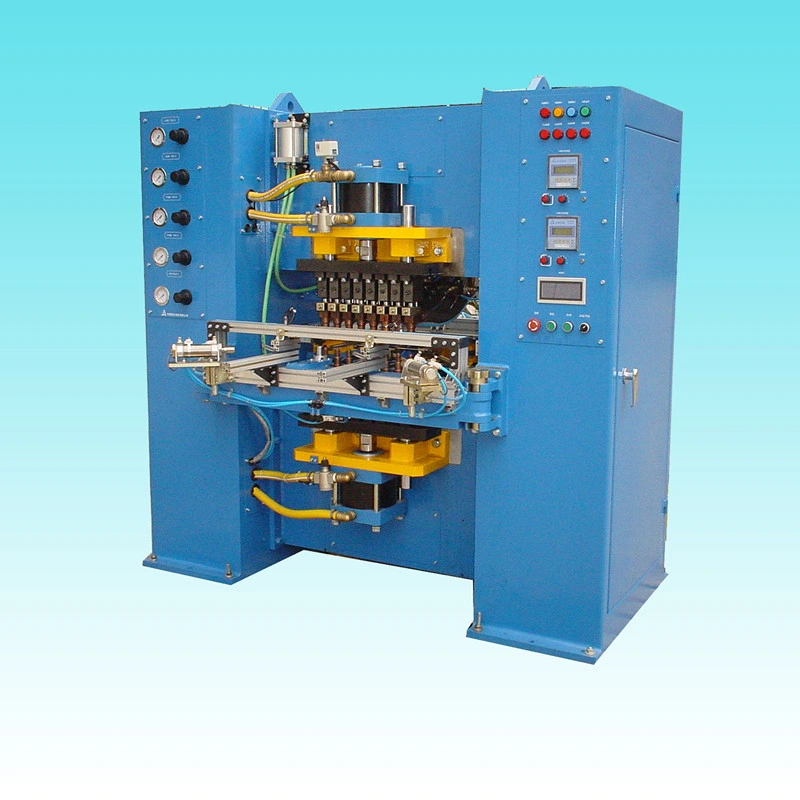

- Detailed Photos

- Company Profile

- FAQ

Basic Info.

Conductive Way

Both-Sided

Welding Spot Number

Single

Type

Special

Application

Steel Grating

Rated Voltage

380V/50Hz

Name

Boss Stitch Welding Machine

Key

Welding Machine

Transport Package

Wooden Case

Trademark

xinchang

Origin

Ningbo

Production Capacity

20 Set / Month

Product Description

Automatic Oil Filled Heater Circumferential Spot Welding Machine

Main Functions

The automatic circumferential spot welding machine(Radiator boss stitch welding machine) is one resistance welding equipment for the boss between the Oil filled heater, It is featured with reliable welding, good sealing, high efficiency, low cost, etc. The mainframe comprises the touch screen, PLC control, silicon controlled rectifier (SCR) as the phase switch, with the high-performance components, the stable welding quality, and the overheating, air pressure, water flow and other protection warning functions.

The pass rate of oil heater after welding≥95% (Calculated by sets).

| 1 | Basic Parameters | |||

| 1.1 | Convex hole distance | 225-490mm (adjustable) | ||

| 1.2 | Convex hole diameter | Φ42-Φ44mm | ||

| 1.3 | Length of Oil filled heater | 325-600mm (regulated according to the workpiece) | ||

| 1.4 | Width of Oil filled heater | 100-180mm (regulated according to the workpiece) | ||

| 1.5 | Max. number of elements per set of radiator | 15 | ||

| 1.6 | Thickness of weldable sheet | 0.4-0.8mm (Ust1203 grade cold-drawn steel sheet) | ||

| 1.7 | Rated voltage | 380V/50Hz | ||

| 1.8 | Rated capacity | 50 × 2 (in the intermediate inverter, energy-saving, stable) | ||

| 1.9 | Duty cycle (%) | 50 | ||

| 1.10 | Secondary no-load voltage (V) | 9.4 | ||

| 1.11 | Secondary max. welding current (KA): | ≥16 | ||

| 1.12 | Total resistance of secondary circuit (μΩ) | ≤50 | ||

| 1.13 | Weldment dimensions | A=D+2*(55-90) (mm); D: 460-480 (mm)(Normal; E: 55-90 (mm) ; B: 100-200 (mm) G: 6(Tl20 (mm); C: 40-45 (mm); F: OC+12 (ram); H: 38-42 (mm) | ||

| 2 | Overall Requirements | |||

| 2.1 | Wire size | ≥35mm2 | ||

| 2.2 | Number of circumferential convex hole welding spots | 32-41 | ||

| 2.3 | Max. welding speed (S) excluding other auxiliary time: | ≤16 seconds/PC (calculated y 38 spots per ring, with reference to 0.5mm low-carbon cold-rolled sheets, steel material complies with EN10130 stamping steel sheet U St grade (or no less than GB/T222 standard, carbon content: 0.05-0.12%) | ||

| 2.4 | Acceptance standards of welding machine: | Comply with the general standards of PRC and the GB15578-1995 national mandatory certification standards. And manufactured in line with the applicable standards, e.g.: JB/T3158-1999, JB3957-1999. | ||

| 2.5 | Controller: | PLC + Touch screen Chinese UI, the controller uses a microprocessor (closed-loop control), current slowly rising, welding spots recorded and number of welding set, 8 sets of welding parameters stored, execution directly selected, with security lock for the setting of welding parameters, startup self-test and system failure self-test, overheating protection and fault indication, etc. Equipped with the master switch and emergency stop button. | ||

| 2.6 | Auxiliary time including each component feeding | About 2-5S (according to different operators) | ||

| 2.7 | Flow of cooling water | ≥30L/min (added with the water flow detection warning system) | ||

| Temperature of cooling water | At the water inlet≤30ºC | |||

| Pressure of cooling water (Mpa) | 0.15-0.3 | |||

| 2.8 | Compressed air (Mpa) | 0.5-0.6 (added with the pressure detection warning system at the compressed air input) | ||

| 2.9 | Max. electrode pressure (N) (0.6Mpa): | ≥3,000 | ||

| 2.10 | Mainframe weight | 1,800Kg | ||

| 2.11 | Repair tools | 1 set per 3 units | ||

| 2.12 | Provided with Mitsubishi touch screen and Mitsubishi PLC, Japan SMC solenoid valve and cylinder assembly, Omron auxiliary relay, Siemens converter; | |||

| 2.13 | Hands-on button control using the mobile station. | |||

| 3 | Configurations | |||

| NO. | Name | Brand/Place of Origin | Remark | |

| 3.1 | Solenoid valve | SMC | ||

| 3.2 | Regulating valve/Filter assembly/Pressure gauge | MindMan | ||

| 3.3 | Air connector/Flow limit valve | SMC | ||

| 3.4 | Master cylinder, 2 sets | Imported components, Japan (World Famous Brand) | Assembled by ourself | |

| 3.5 | Welding controller system, 2 sets | Anda, independent development | The arm rotary cylinder part uses SMC components | |

| 3.6 | Main converter, 2 sets | Anda | Epoxy resin package | |

| 3.7 | Inverter, 2 sets | European imported elements | Designed and assembled by Anda | |

| 3.8 | Touch screen, 1 set | Mitsubishi | ||

| 3.9 | PLC/Touch screen | Mitsubishi | ||

| 3.10 | SCR/ Diode/IGBT | Ximenkan or equivalent foreign brands | ||

| 3.11 | Auxiliary relay | Omron or equivalent foreign brands | ||

| 3.12 | Proximity switch | Autonics | ||

| 3.13 | Button switch | Siemens/ Schneider | ||

| 3.14 | Power switch | Mitsubishi/Japan | ||

| 3.15 | Stepping motor, 2 sets | Sanyo/Japan | ||

| 3.16 | Driver, 2 sets | Domestic | ||

| 3.17 | Time relay | Omron | ||

| 3.18 | Bearing | Wholly Imported, Famous Brand | ||

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in friction welding machine, resistance welding machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.

Over the years, we have exported so many machines to 30 and more countries, such as France,Spain,Poland,Russia,Indonesia,Vietnam,Pakistan,India,Mexico,Egypt etc.

Our main products are Heat exchanger equipment, Friction welding machine, spot welding machine, projection welding machine, butt welding machine, seam welding machine, multi head welding machine for wire mesh, and other various special welding machine for metal connection in different industries.

We always adhere to the management idea of "Integrity, profession, innovation, and win-win", to make Xin Chang becomes trustworthy enterprise of customers. Good product quality, perfect after-sales service, and professional technical support make customers choose no regrets and worry-free use

1.Q: What about your standard delivery date ?

1.Q: What about your standard delivery date ? A: Usually 30-60 working days. Our company provide just-in-time delivery

2.Q: How can you guarantee quality?

A: You could test samples before order,and we have professional QC and precise machining equipment; Always final Inspection before shipment;

3.Q: How long is the guarantee?

A: For one year after the custumer received the machine.

4.Q: What do we need to do if the machine fails?

A: In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.

5.Q: Can I make my own design and logo on the product?

A: Yes, we do OEM.Welcome global partners.

6.Q: what is the packing mode?

A: wooden case or FCL with container.

7.Q: what is your after-sell service?

A: After-Sales

1) Training your workers how to install the machine, how to use the machine.

2) Engineers available to service machinery overseas

3) 1-year guarantee ( free maintain in a year)

4) Replacement parts and other accessories provided