Basic Info.

Model NO.

Customized CNC machining axle shaft

Appearance Shape

Round

Journal Surface Roughness

0.63-0.16μm

Name

Sand Casting/Precision Casting/Machining Shaft

Technology

CNC Machining

Type

Drilling, Tapping, Milling, Grinding, Laser

Quality Certification

ISO 9001:2008, AISI, CE, Ieo, SGS

Weight

0.5-50 Kgs

Tolerance

as Drawing or Request

Strict QC

Reliable Quality with High Precision 0.05

Surface Finish

Zinc, Anodising, Powder Coated, Electric Platin

Other Material

Iron/ Steel/ Aluminum/ Brass

Delivery

30 Days After Payments

Transport Package

Gunny Bag/Wooden Crate/Iron Drum+Pallet

Specification

OEM shaft

Trademark

XH

Origin

China

HS Code

8460190000

Production Capacity

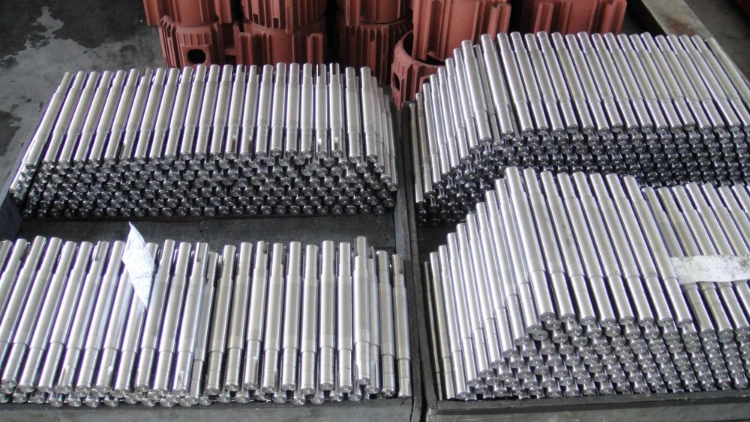

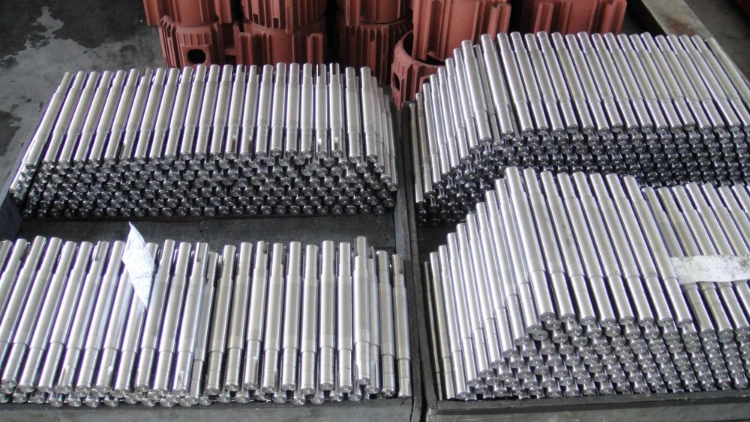

200tons to 500tons Per Month

Product Description

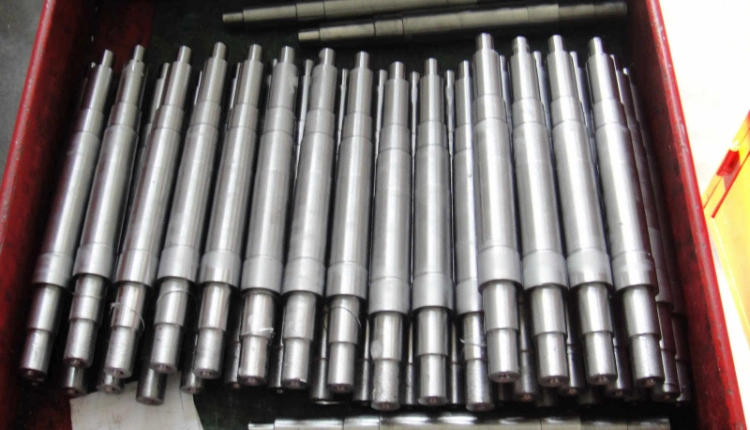

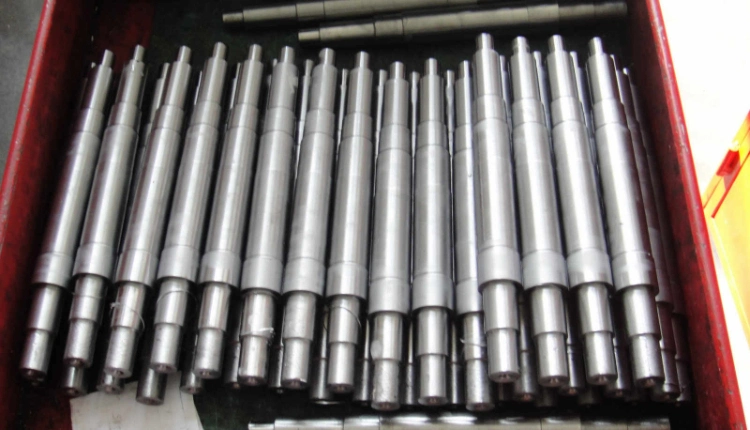

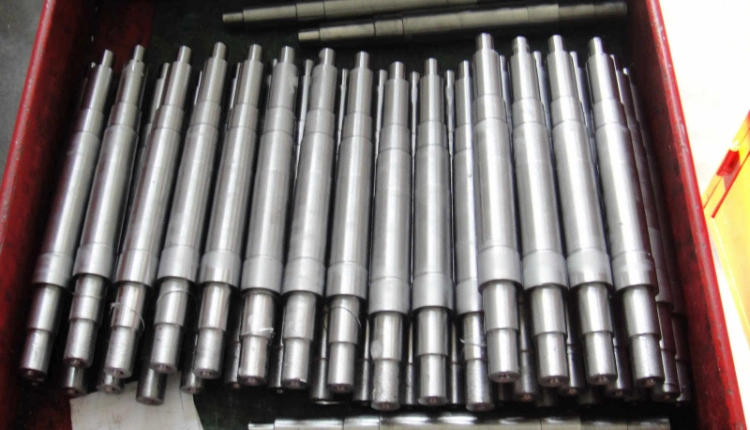

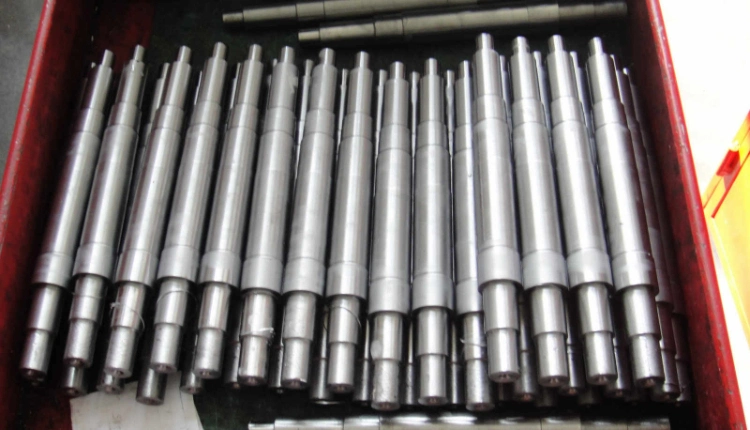

Customized CNC Machining Axle Shaft with Precision Casting

1. Material: Cast iron; Steel; Aluminium; Stainless steel

2. Process: Casting; Machining; Treating

3. Machining equipment: CNC Machine, vertical centers, miling machine, lathe machine

4. DNT equipment: X-ray detector, UT, MT

5. Professional investment casting foundry, 10 years experience and expertise. Most products are exported to Europe and North American markets. Main material is carbon steel, low alloy steel and stainless steel. Heat treatment, machining and finishing are available.

6. Trademark: OEM

7. Model: Purchaser's Part Number

8. Standard: ISO9001

Productivity: 500 MT/month

Origin: Made In China

Packing: Eurpean standard pallet size

Transportation: By Air/Sea

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Produce will be based on customers' drawing, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, SolidWorks, etc.

Casting capability: 200-500 tons / per month.

Machining process: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and working hard employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Hope we can build good cooperation with you.

1. Material: Cast iron; Steel; Aluminium; Stainless steel

2. Process: Casting; Machining; Treating

3. Machining equipment: CNC Machine, vertical centers, miling machine, lathe machine

4. DNT equipment: X-ray detector, UT, MT

5. Professional investment casting foundry, 10 years experience and expertise. Most products are exported to Europe and North American markets. Main material is carbon steel, low alloy steel and stainless steel. Heat treatment, machining and finishing are available.

6. Trademark: OEM

7. Model: Purchaser's Part Number

8. Standard: ISO9001

Productivity: 500 MT/month

Origin: Made In China

Packing: Eurpean standard pallet size

Transportation: By Air/Sea

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Produce will be based on customers' drawing, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, SolidWorks, etc.

Casting capability: 200-500 tons / per month.

Machining process: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and working hard employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Hope we can build good cooperation with you.

| PROCESS | MATERIAL | STANDARD | |

| Sand Casting | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon, Steel, Aluminum, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| Investment casting | Sodium Silicone (Water glass) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| Forging | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| Stamping Machining | Stamping Machining | All metal material | |

| Surface finish process | Shot blast, chromate plating, power coated and anodizing | ||

| machining | Turning and cutting, milling, grinding, drilling, reaming and threading | ||