Basic Info.

Model NO.

HP 600/630-37/1040E

Core

Single Core

Certification

RoHS, CE, ISO9001, CCC

Brand

Fcj Opto Tech

Sheath Material

ETFE or Acrylate

Core Material

Pure Silica Glass,Doped Silica Glass

Cladding Material

Fluoroacrylate

Coating Material

ETFE or Acrylate

Oh Content

Low Oh

Transport Package

Carton

Specification

1km, 2km

Trademark

FCJ OPTO TECH

Origin

China

HS Code

8544700000

Production Capacity

20 Million Kilometers

Product Description

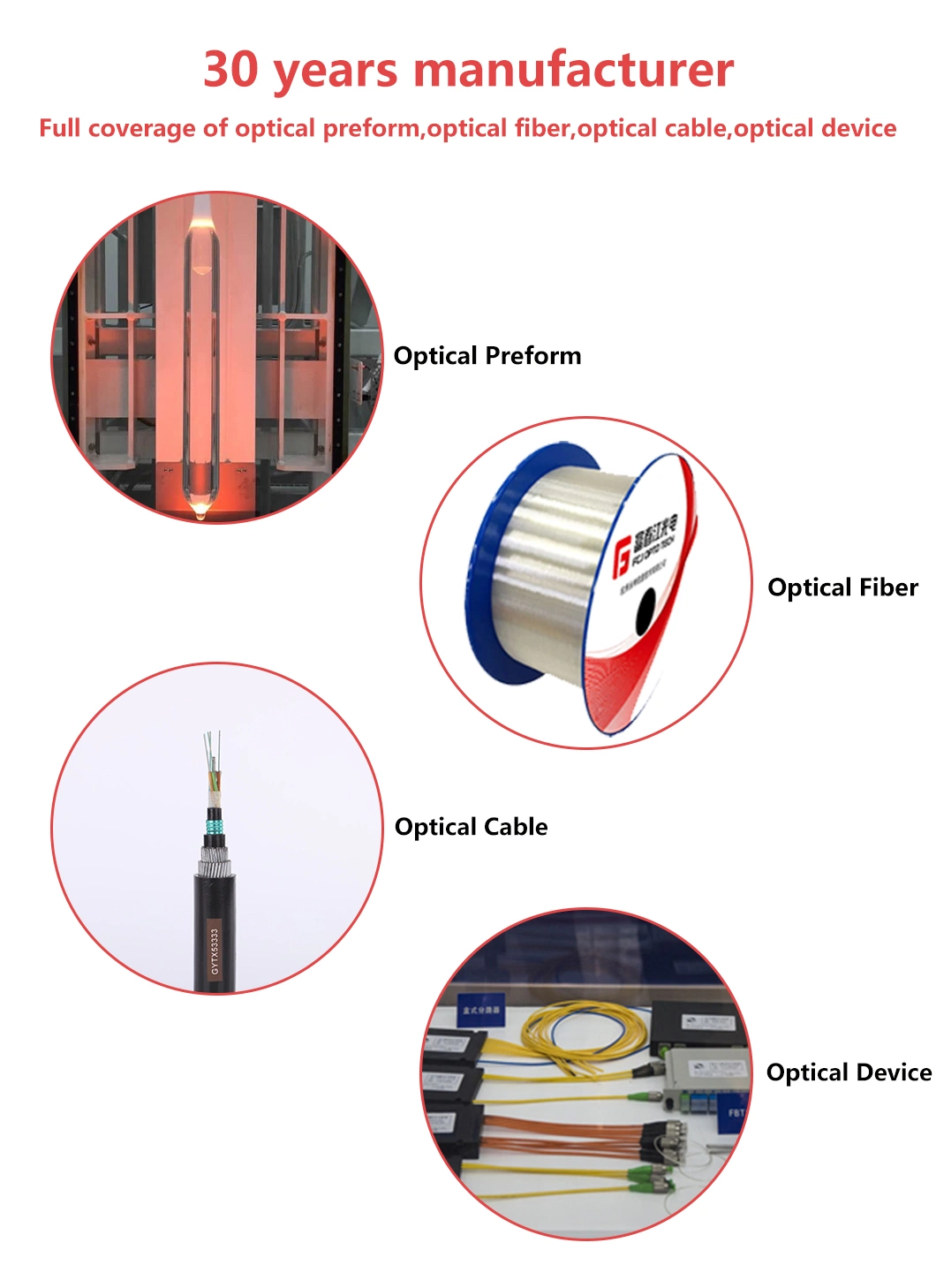

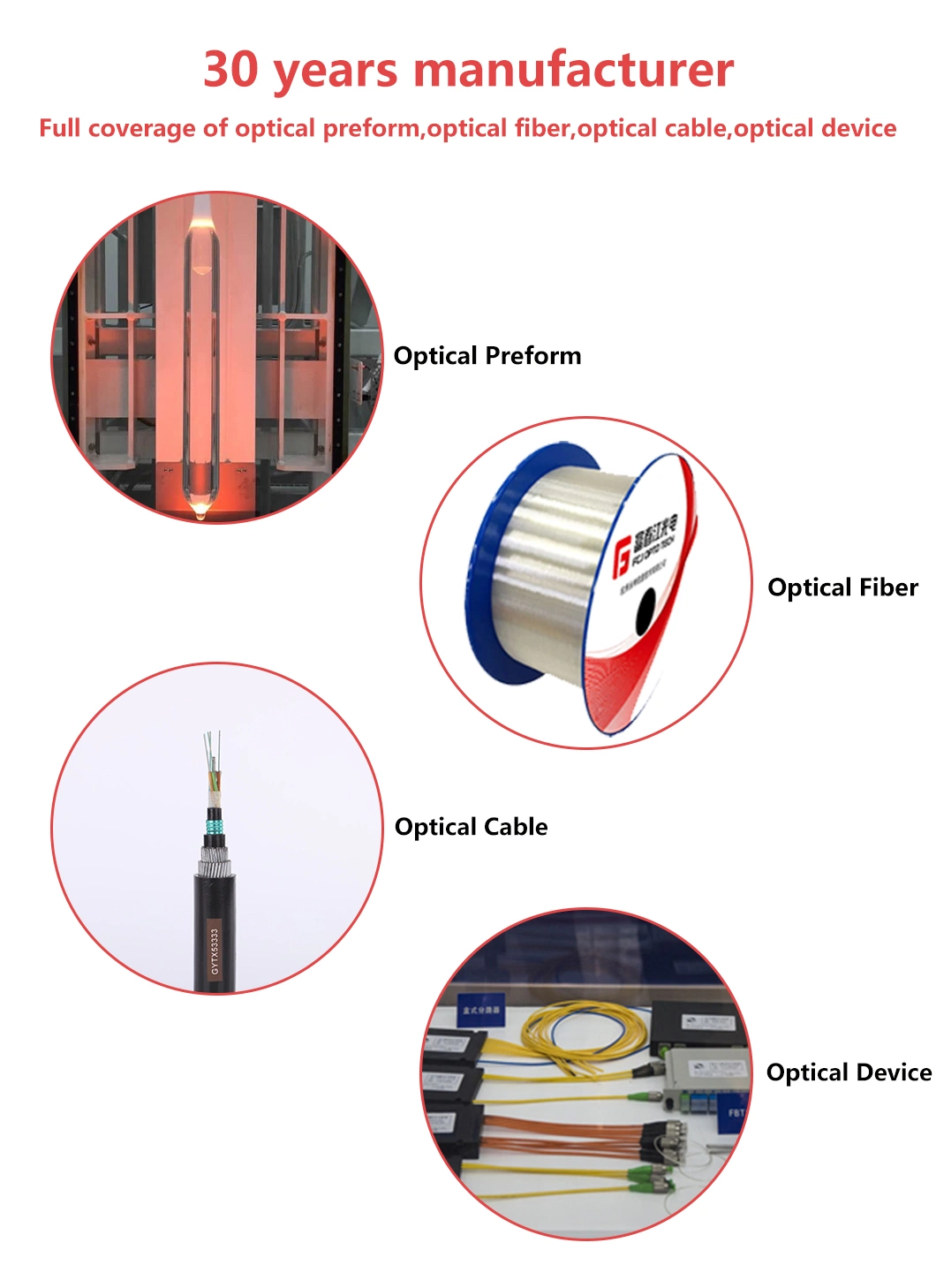

Hard Polymer Cladding Optical Fiber (HPCF)

Applications :

• High energy laser transmission

• Short-to-medium distance telecommunication

• Electric signal transmission

• Locomotive traction control

• Medical sensor

• Factory automation control

• Laser therapy and operation

• Near-IR spectroscopy application

• Optical pyrometry

• Nuclear radiation monitoring

• Optical fibre lighting

Characteristics

• Higher coupling efficiency provided than LED and lasersource

• Tolerant of wide fluctuations in temperature and humidity

• More effective and cheaper connection mode

• Excellent fatigue resistance performance

• Excellent radiation resistance performance

• Compatible with a variety of light sources

Packaging and storage

Applications :

• High energy laser transmission

• Short-to-medium distance telecommunication

• Electric signal transmission

• Locomotive traction control

• Medical sensor

• Factory automation control

• Laser therapy and operation

• Near-IR spectroscopy application

• Optical pyrometry

• Nuclear radiation monitoring

• Optical fibre lighting

Characteristics

• Higher coupling efficiency provided than LED and lasersource

• Tolerant of wide fluctuations in temperature and humidity

• More effective and cheaper connection mode

• Excellent fatigue resistance performance

• Excellent radiation resistance performance

• Compatible with a variety of light sources

| Specifications · | |||||

| Specifications-1 | |||||

| Fiber Type | HP 200/230-37/500E | HP 200/230-40/500 | HP 200/230-46/500 | HP 300/330-37/650E | HP 400/430-37/730E |

| Optical Properties | |||||

| Numerical Aperture | 0.37±0.02 | 0.40±0.02 | 0.46+-0.02 | 0.37±0.02 | 0.37±0.02 |

| Attenuation@850nm (dB/km) | ≤8.0 | ≤5.0 | ≤8.0 | ≤8.0 | ≤8.0 |

| OH Content | Low OH | Low OH | Low OH | Low OH | Low OH |

| Refractive Index Profile | Step Index | Grade Index | Step index | Step Index | Step Index |

| Geometrical Properties | |||||

| Core Diameter(μm) | 200.0±3.0 | 200.0±3.0 | 200.0±3.0 | 300.0±6.0 | 400.0±8.0 |

| Cladding Diameter(μm) | 230+0/-8 | 230+0/-8 | 230+5/-10 | 330+5/-10 | 430+5/-10 |

| Coating Diameter(μm) | 500.0±25.0 | 500.0±25.0 | 500.0±20.0 | 650.0±30.0 | 730.0±30.0 |

| Core Concentricity Error(μm) | ≤5.0 | ≤5.0 | ≤5.0 | ≤6.0 | ≤8.0 |

| Material Composition | |||||

| Core Material | Pure Silica Glass | Doped Silica Glass | Pure Silica Glass | Pure Silica Glass | Pure Silica Glass |

| Cladding Material | Fluoroacrylate | Fluoroacrylate | Fluoroacrylate | Fluoroacrylate | Fluoroacrylate |

| Coating Material | ETFE | Acrylate | Acrylate | ETFE | ETFE |

| Mechanical Properties | |||||

| Short Term Bend Radius(mm) | ≥10 | ≥10 | ≥10 | ≥16 | ≥29 |

| Long erm Bend Radius(mm) | ≥16 | ≥16 | ≥16 | ≥24 | ≥47 |

| Operating Temperature (ºC) | -65 to +85 | -65 to +85 | -65 to +85 | -65 to +85 | -65 to +85 |

| Proof Test Level(kpsi) | 100 | 100 | 75 | 100 | 75 |

| Specifications-2 | |||

| Fiber Type | HP 600/630-37/1040E | HP 600/630-37/750E | HP 1000/1100-37/1400E |

| Optical Properties | |||

| Numerical Aperture | 0.37±0.02 | 0.37±0.02 | 0.37±0.02 |

| Attenuation@850nm (dB/km) | ≤8.0 | ≤8.0 | ≤8.0 |

| OH Content | Low OH | Low OH | Low OH |

| Refractive Index Profile | Step Index | Step Index | Step Index |

| Geometrical Properties | |||

| Core Diameter(μm) | 600.0±10.0 | 600.0±10.0 | 1000.0±20.0 |

| Cladding Diameter(μm) | 630+5/-10 | 630+5/-10 | 1100+10/-30 |

| Coating Diameter(μm) | 1040.0±30.0 | 750.0±30.0 | 1400.0±50.0 |

| Core Concentricity Error(μm) | ≤8.0 | ≤8.0 | ≤10.0 |

| Material Composition | |||

| Core Material | Pure Silica Glass | Pure Silica Glass | Pure Silica Glass |

| Cladding Material | Fluoroacrylate | Fluoroacrylate | Fluoroacrylate |

| Coating Material | ETFE | ETFE | ETFE |

| Mechanical Properties | |||

| Short Term Bend Radius(mm) | ≥58 | ≥58 | ≥73 |

| Long erm Bend Radius(mm) | ≥94 | ≥94 | ≥118 |

| Operating Temperature (ºC) | -65 to +85 | -65 to +85 | -65 to +85 |

| Proof Test Level(kpsi) | 75 | 75 | 85 |

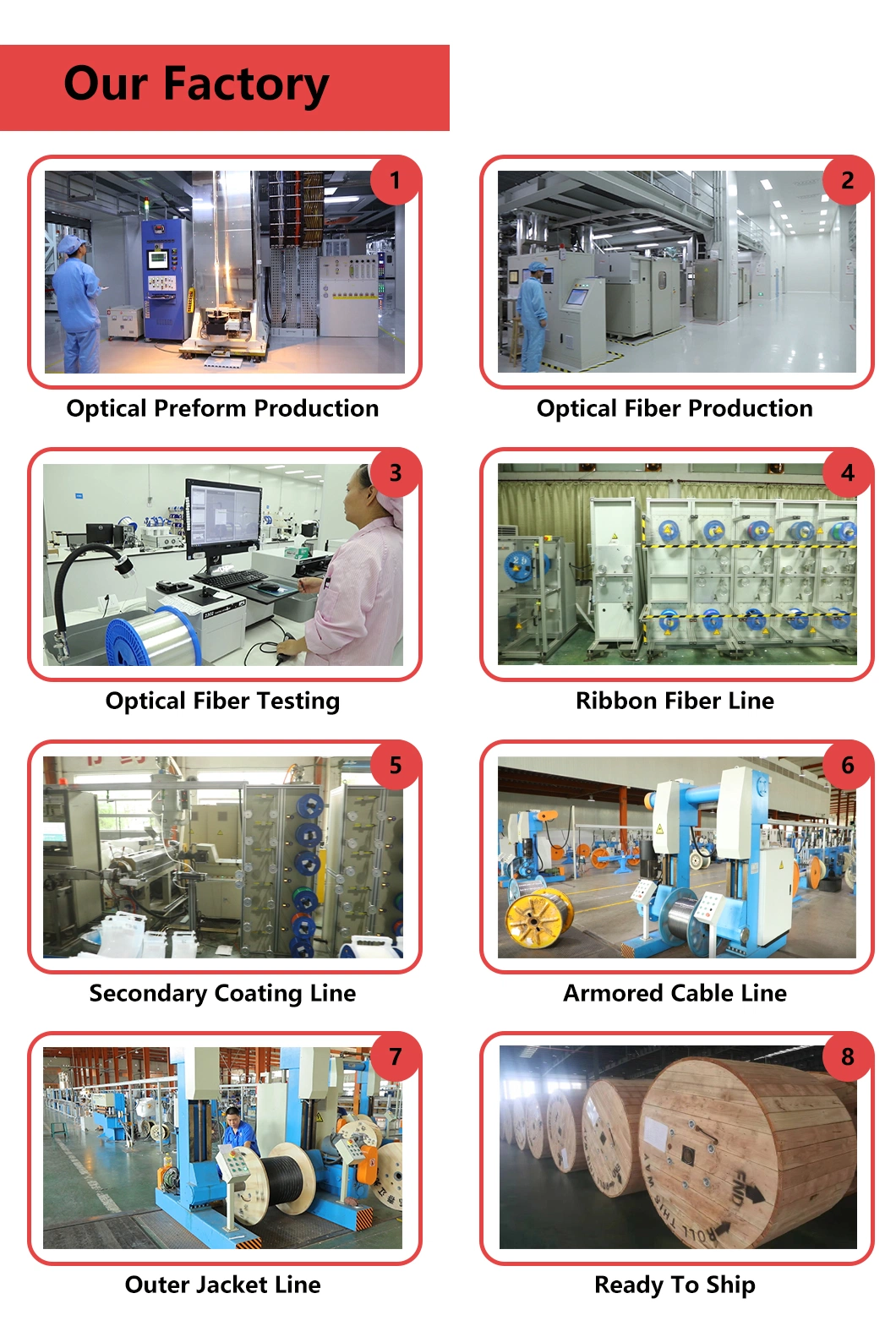

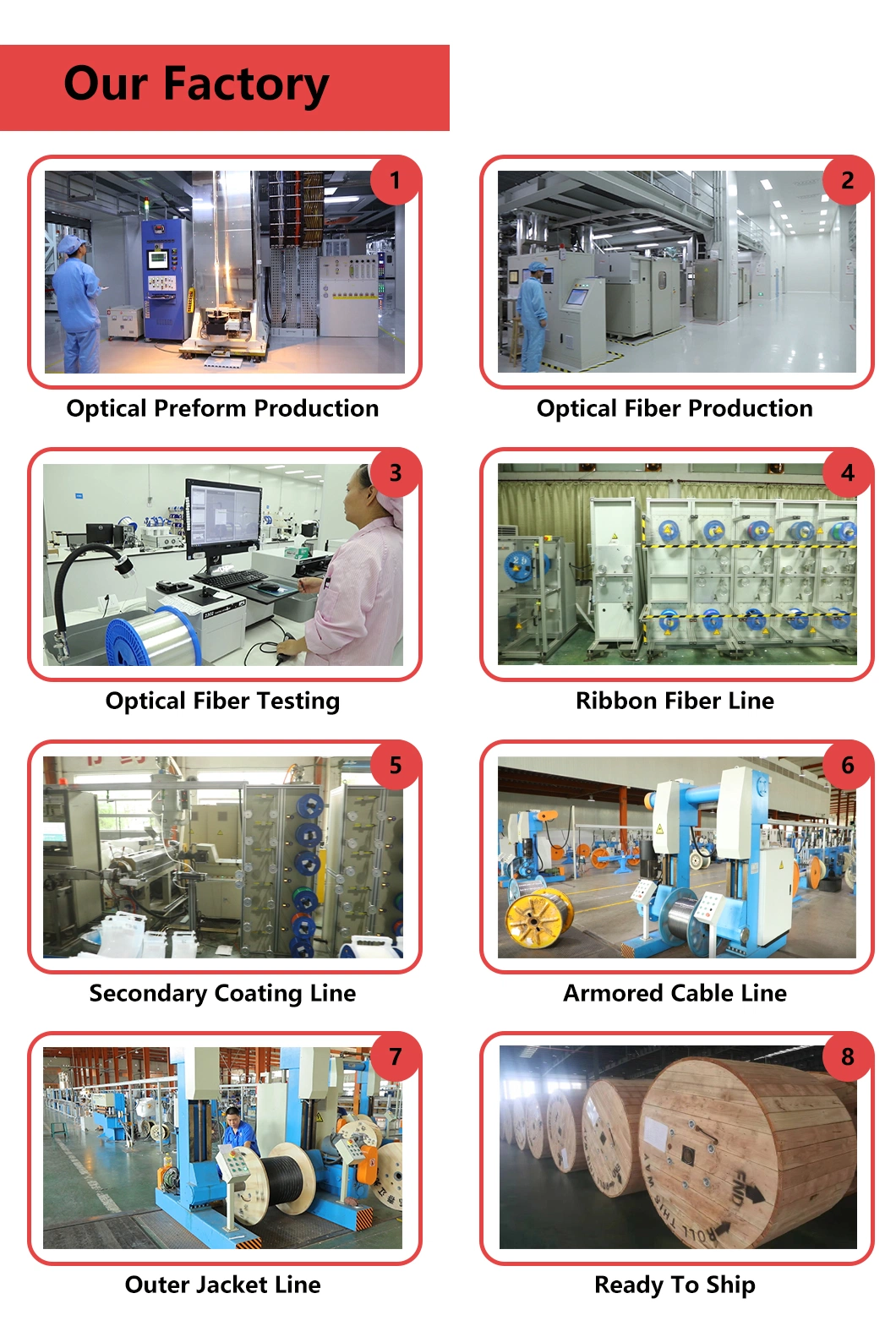

Packaging and storage

- Ensure no foreign matter on the reel and fiber surface, wrap it with film and cover, and label fiber coding on the reel and cover respectively.

- The packaged optical fiber is stored at a constant temperature of 25ºC in a light-proof warehouse. The products are fixed in the carton when they are shipped out of the warehouse. The carton number and fiber coding information are attached to the carton, and the electronic test report is attached to each shipment.